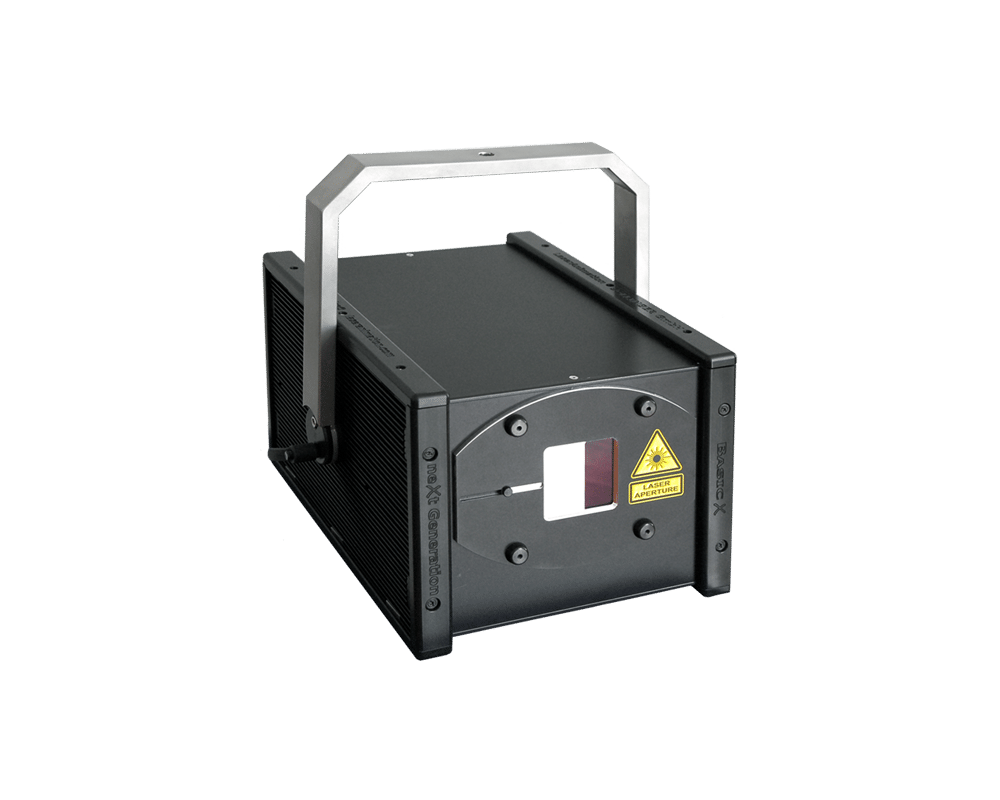

LA.Toolbox Software

With this intuitive software it is possible to control important functions of the laser projector and adjust operating values. The LA.Toolbox is available as a PC version and Mac version. Both are supplied with every laser projector and are also available for download.

- horizontal, vertical size

- inversion

- position offset

- keystone correction and rotation can be exactly adjusted with sliders in the clearly laid out “Projection” menu and saved in 3 different transformation settings.

The states of all laser sources can be monitored, the power can be scaled and the behavior of the laser with a small modulation signal can be adapted slightly through the “Bias Offset”. This setting allows the best possible adjustment of the effective soft blanking of the Lasergraph DSP.

The states of all laser sources can be monitored, the power can be scaled and the behavior of the laser with a small modulation signal can be adapted slightly through the “Bias Offset”. This setting allows the best possible adjustment of the effective soft blanking of the Lasergraph DSP.

With this new safety technology we give users the option to use a graphics editor to flexibly define protected areas in a laser projection. The editor can be used in way similar to a vector based graphics program to create a mask from geometric shapes (polygons, circles and rectangles). Safety parameters can then be defined individually for each of these shapes.

Two different mask functions are available:1. Electronic Mask This important function allows limiting the laser output for certain areas. The intensity of the laser beam can be adjusted in a range from 0% to 100% for each individual shape created with the editor. This makes it possible to correctly protect specific scanning areas such as the auditorium or sectors with optical equipment (video beamers, cameras). The big advantage of this mask, which is configured in the projector, compared to a mask generated in the show controller is the fact that programming errors which may occur when a show is edited will not disable the mask.

2. Safety Mask For safety reasons every laser projector is equipped with a scanner safety circuit to protect the audience. This mechanism determines the sum of the scanner velocities for the horizontal and vertical deflection of the beam and compares this to the predefined minimum speed. In case the beam velocity is below the minimum or if the beam is completely motionless this safety mechanism will block the laser beam.

For allowing beam effects with a stationary beam anyway in areas where the audience is not at risk, for instance below the ceiling, the “Safety Mask” can be used to graphically define several areas where a static beam will be possible, see picture. (Up to now only one rectangular safety area could be defined.)

The position of the individual beams can change over time when the projectors are frequently transported, set up and taken down again. Until now the beams could only be adjusted using the small adjustment screws on the side of the device. In everyday use the projectors are often already installed in a stage setup, e.g. attached to a truss high up, when the laser is turned on and the beam misalignment is discovered. This used to mean the laser had to be taken down again for adjustment. This considerable effort is no longer necessary using the “Beam Adjust” of the LA Toolbox Software.

Up to 4 settings can be saved. The DMX base address can easily be configured using the software.